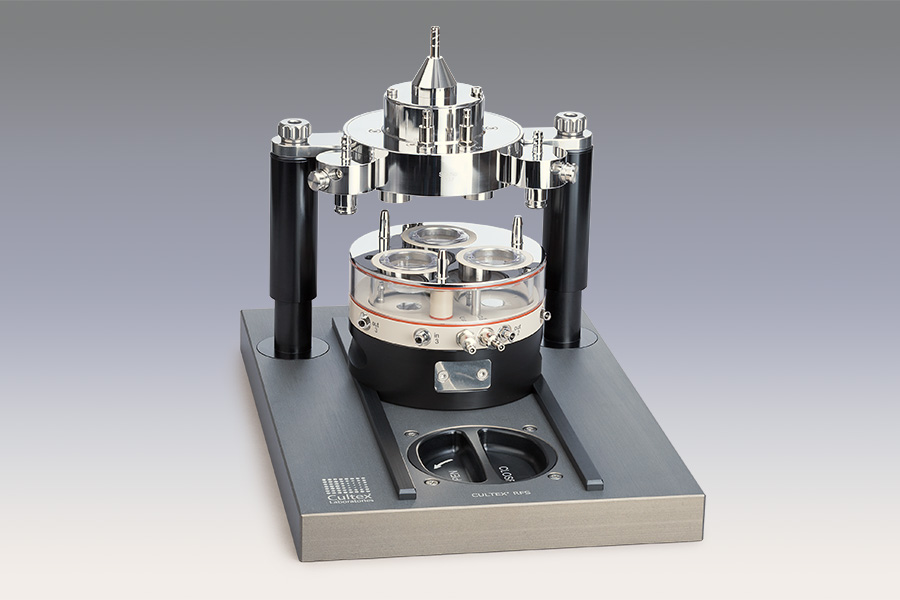

Radial Flow System for cell-based exposure

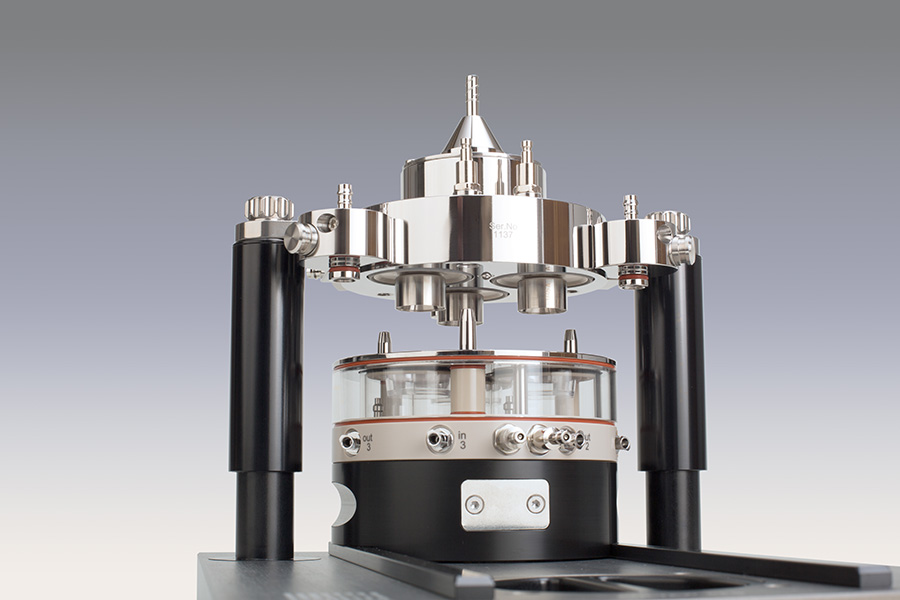

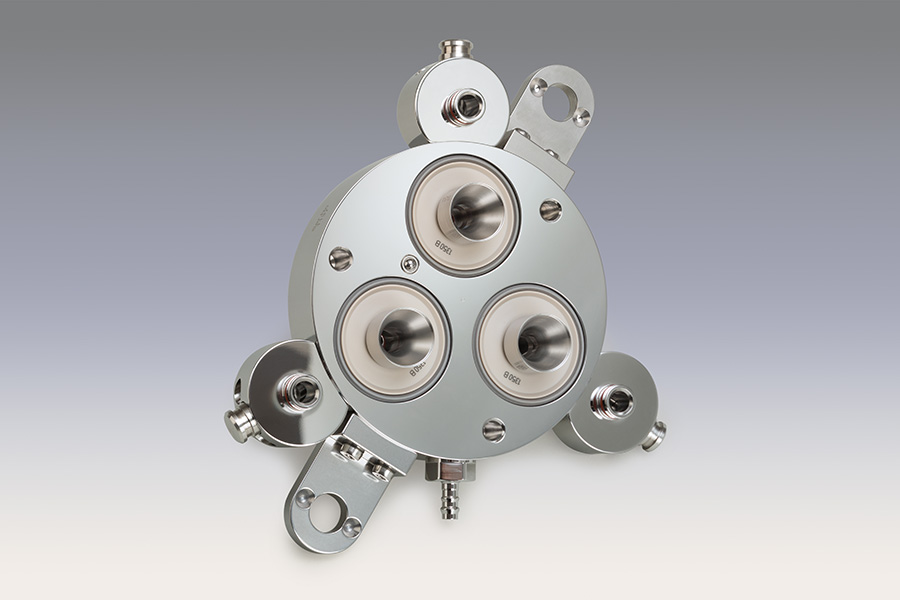

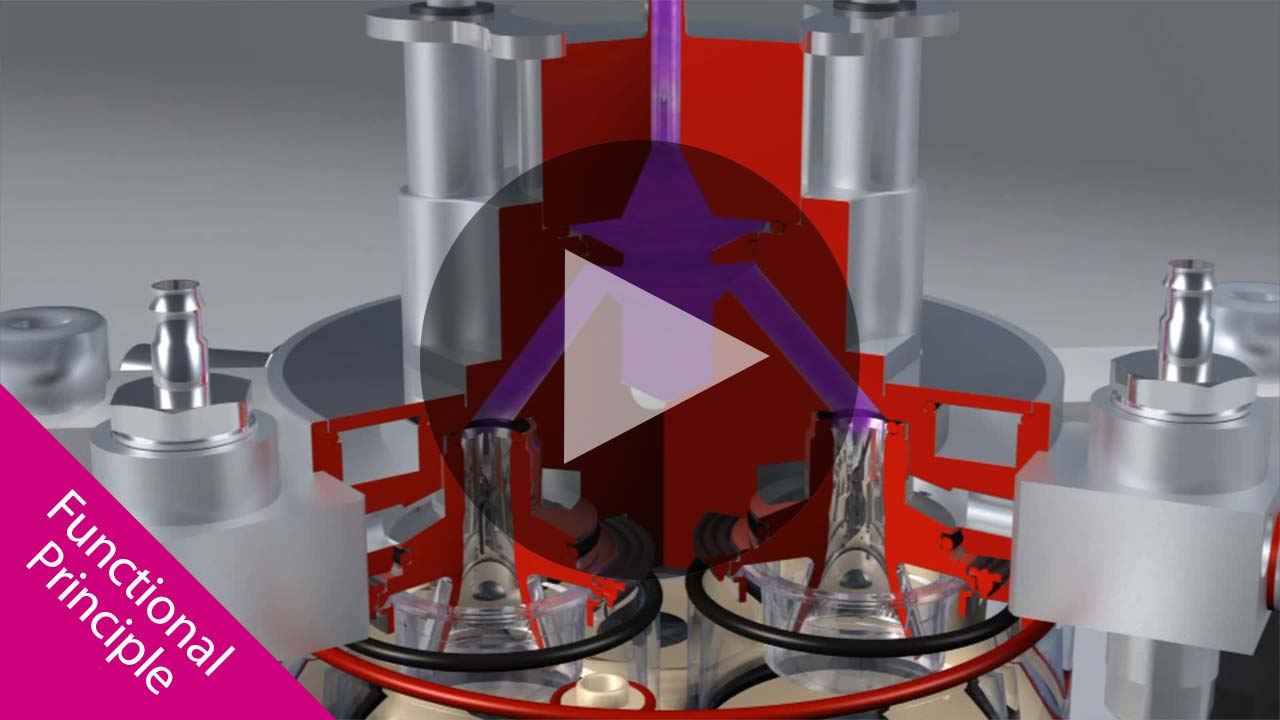

This is a high-end exposure system for the direct exposure of cell culture inserts or Petri dishes. The modular system consists of two main parts, the aerosol-guiding module and the sampling module housing the cell culture inserts, or Petri dishes.

The aerosol-guiding module can be fitted tightly to the sampling module, thus realizing a close connection between the two parts before exposure. The sampling module houses three cell culture inserts (or Petri dishes), which can be separately supplied with medium.

The modular concept of CULTEX® product solutions allows simple, investment-safe upgrading of the CULTEX® RFS with a wide range of enhancement systems:

- CULTEX® EDD Module – well-engineered Electrical Deposition Device to increase the deposition efficiency for micro-sized and nano-sized particles

- CULTEX® DG Module – our Dust Generator recommended as essential peripheral equipment for the exposure of cells to dry powder aerosols

- CULTEX® HyP Module – our high-precision Hydraulic Press for the production of homogeneous dust cakes for uniform aerosol generation and reproducible results

- CULTEX® Insertomat – a helpful device for the excision of the delicate microporous membranes from cell culture inserts for histopathology

- CULTEX® Process Plate – facilitates the processing of Falcon® and Transwell® inserts

CULTEX® RFS – the recipient of several awards

The cell culture reactor CULTEX® RFS has already received the Dr. Rudolf Eberle Prize, the innovation prize awarded by the State of Baden-Württemberg. As emphasized in the laudatory speech, this prize represents the recognition of new technological developments of the highest standard. The precision system manufactured from the highest quality materials is in the meantime also being successfully used in a project to test the method for direct exposure of cells, in which various research groups are assessing the stability, reproducibility and validity of the method on different sized particles up to nanoparticles, to establish fundamental legally recognized principles for a testing system.

Exposure systems

General features

- Direct exposure technology at the air-liquid interface of

cell cultures - Cellular systems: cell lines and primary cells from the

respiratory tract as mono- or co-cultures - Test compounds

- Gases

- Particles (fine to nanoparticles)

- Complex mixtures (e.g. tobacco smoke)

- Application areas

- Industrial chemicals (particulate & gaseous compounds)

- Consumer products

- Tobacco smoke

- E-cigarette vapor

- Pharmaceutical and therapeutic products

- Pesticides

- In- and outdoor analysis

- Clients

- Universities

- Regulatory Bodies

- Military

- Pharmaceutical, chemical and tobacco industry

- Contract research laboratories

Basic principles of the exposure systems

Module design

- Inlet adapter

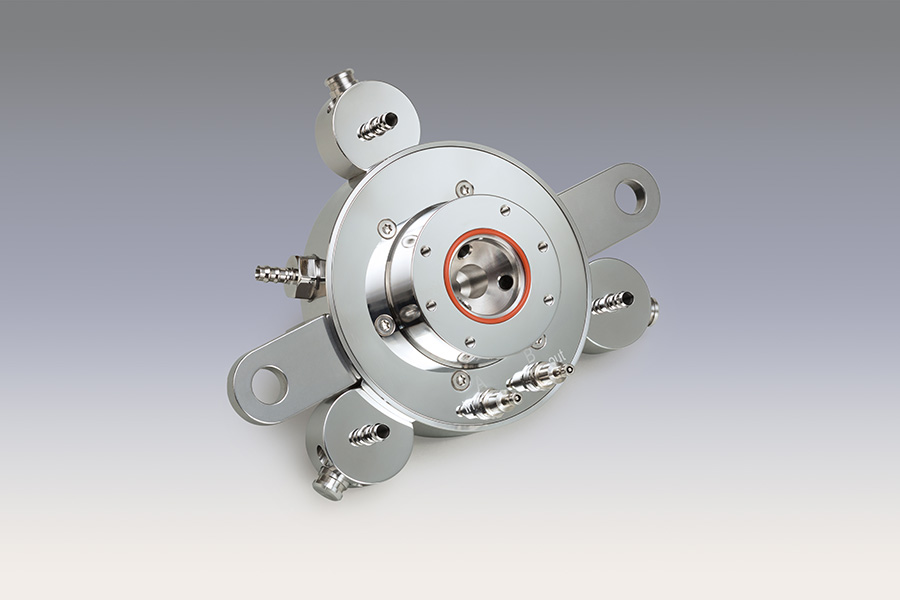

- Exposure top – Aerosol guiding module

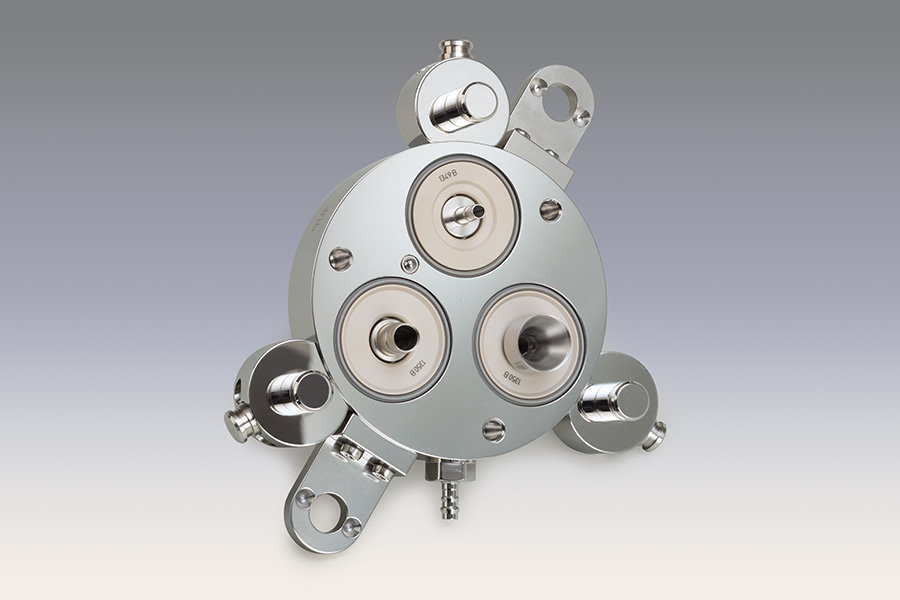

- Base module – Sampling module

- Socket module

- Locking module

Dilution

- Use of the system with or without dilution

Test atmosphere

- One sampling point

- Radial flow system

- Homogenous distribution of the test atmosphere to the surface of the cells

- Reproducible deposition of the particles on the cell surface

- Establishment of dose-response relationships

- Repeated exposure studies

Biological test system

Cells

- Maintenance of cell viability

- 37° C by a temperature-controlled flow of water

- Medium supply from below the insert membrane

(static, intermittent, continuous)

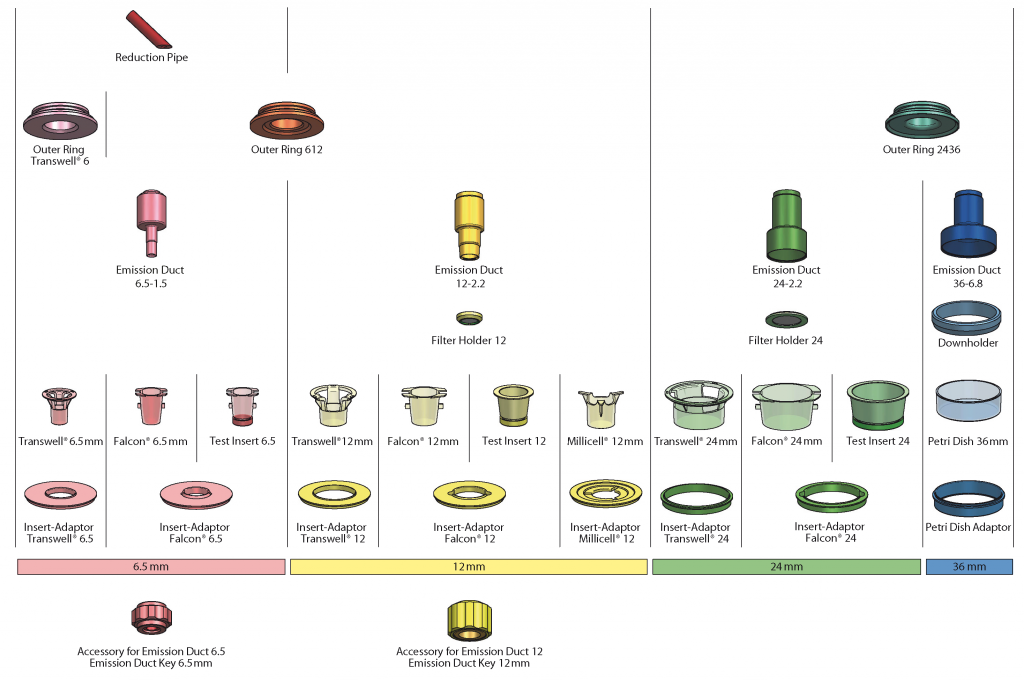

- Application of 6.5 mm, 12 mm and 24 mm Falcon®

or Transwell® inserts via special adapters

Bacteria

- Special adapter for 35 mm Petri dishes for running a modified Ames assay

Air-liquid interphase – in vitro exposure

Exposure systems – CULTEX® RFS – Radial Flow System

- Flexible design of the exposure top with aerosol inlets for

commercial available membrane inserts (Falcon®/Transwell®)

of different size and 35 mm Petri dishes - 3 exposure positions

- Individual exposure chambers (3 membrane inserts)

- Tempering of the exposure chambers

- Individual medium supply of the independent exposure

chambers